Low-temperature treatment achieves coatings with the same degree of hardness or higher than TD treatment or CVD. Dimensional changes and distortion of materials can be reduced.

*Steel must be tempered at least twice at 520°C or higher.

By applying Y-coat to molds, “abrasion and galling resistance, improved slipperiness, weld adhesion resistance, and heat resistance” can be obtained, thereby extending the life of molds and ensuring consistent quality.

In addition, our unique coating removal and recoating technology enables reuse of molds, contributing to resource conservation and cost reduction.

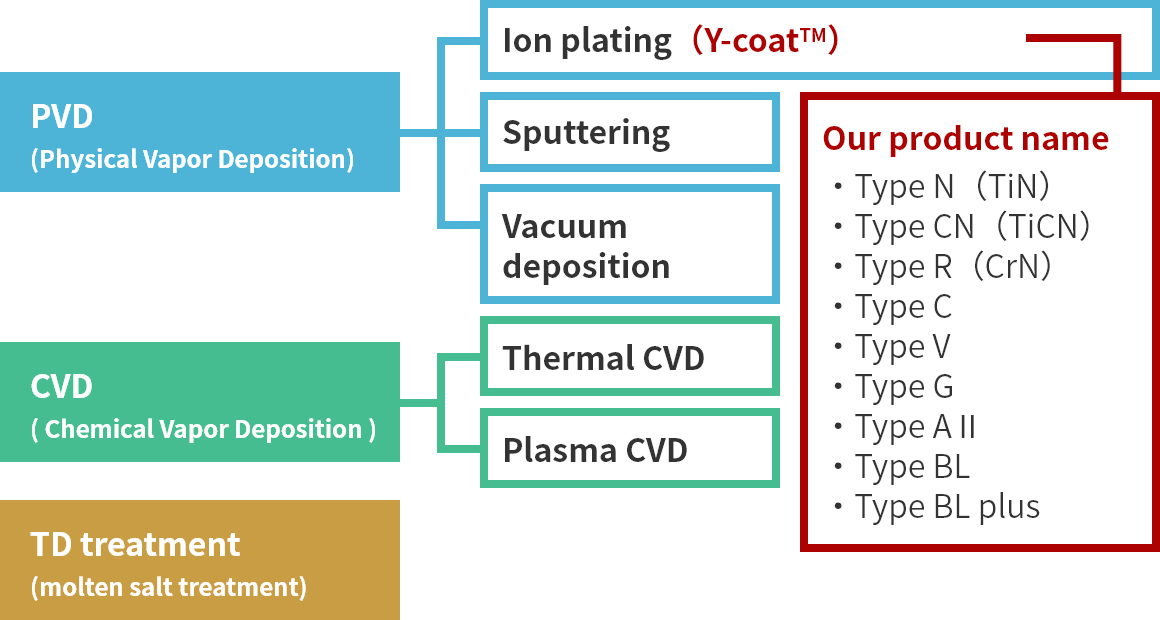

Method of coating film on molds

Unique coating technology of Yuken Industry

POINT1

Pre-treatment technology based on the expertise of a cleaning agent manufacturer provides excellent adhesion of PVD films.

POINT2

Low temperature treatment (less than 500°C) minimizes dimensional change and distortion of the material.

POINT3

We can also remove coatings on carbide by utilizing its technological capabilities as a chemical manufacturer.

POINT4

Damage analysis capability and quality assurance.

Our coating process utilizes proprietary technologies developed as a pioneer in the field of cleaning agent manufacturing.

Unique mold cleaning technology leveraging the expertise of a cleaning agent manufacturer

Whether or not the coating adheres well is determined by the cleaning process.We have developed our own mold cleaning technology by leveraging the expertise of a cleaning agent manufacturer.

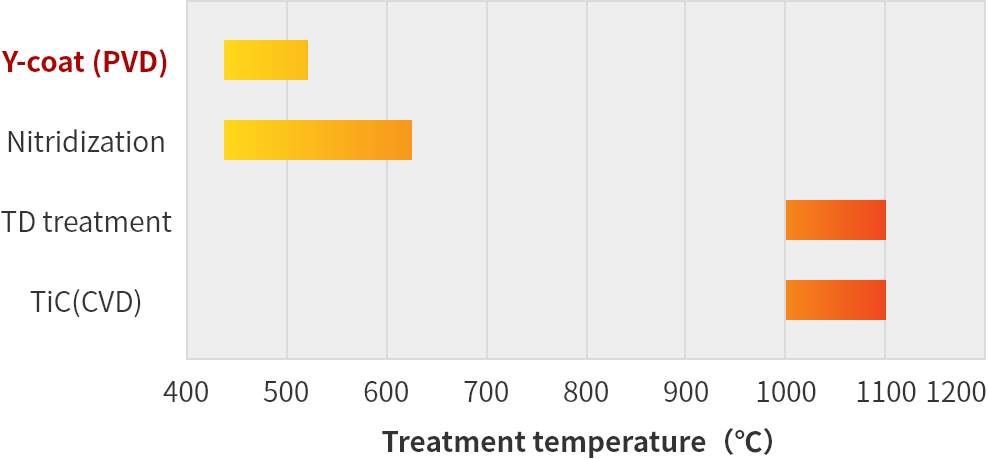

Low temperature treatment (500°C) minimizes dimensional changes and distortion of the material

Low-temperature treatment achieves coatings with the same degree of hardness or higher than TD treatment or CVD. Dimensional changes and distortion of materials can be reduced.

*Steel must be tempered at least twice at 520°C or higher.

Treatment temperature for each surface treatment

Unique film removal technology that leverages our development strengths as a chemical manufacturer

Our technological development as a chemical manufacturer has made it possible to dissolve and remove not only PVD, but also CVD and TD coatings using chemicals. Also, by controlling surface roughness after film removal, we have made it possible to recoat used molds.

For CVD and TD treatment (using shot blasting)

The film removal roughens the mold surface and requires extensive wrapping.

(See figure on the right: Surface after removal of film by shot blasting ×500)

For Y-coat (using dissolution and removal)

A simple wrap can be used to maintain a mirror surface after film removal.

(See figure on the right: Surface SKH51 ×500 after removal of film by dissolution)

Damage analysis capability and quality assurance

Based on our extensive experience in mold analysis, we perform “magnified observation,” “residual film thickness measurement,” and “cross-sectional analysis” of damaged molds.

We provide reliable quality and after-sales service with our well-trained staff and analyzers.

Inquiries about TL Division

CONTACT US

For Q&A and inquiries about our products, please contact us here.