Chemicals For Electronic Components

What are electronic component chemicals?

Chemicals for electronic components are used in everyday life

Flexible base

Contact

Plating for joints

External interface

Exterior

Joint plating

Semiconductor

Exterior plating

Connector

Contact

Joint plating

Plating line process

This shows each plating line process.

Hoop (continuous) plating line process

- Dipping degreasing

- Electrolytic degreasing

- Electrolytic machining

- Ni plating

- Plating

- Aftertreatment

Semiconductor rack and rackless plating line process

- Dipping degreasing

- Electrolytic deburring

- Electrolytic machining

- Plating

- Aftertreatment

Sn plating process (Metasu FSM series)

Sn plating for connectors (Metasu FSM-07)

Features

- Produces a uniform matte appearance independent of current density.

- Good solder wettability and whisker characteristics are achieved.

- Can also be used for reflow Sn specifications.

- Excellent bath stability due to running.

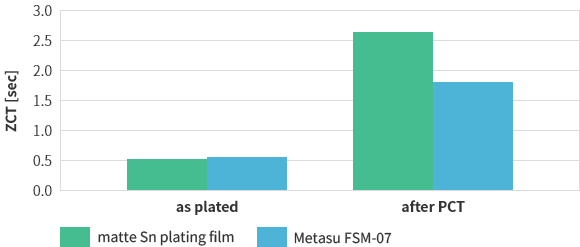

Metasu FSM-07 solder wettability of plating film

The plating film of Metasu FSM-07 is formed with much less degradation of solder wettability compared to the conventional matte Sn plating film.

Sn plating for semiconductors (Metasu FSM series)

Features

- The plating chemicals are used in the semiconductor market.

- Uniform crystals can be achieved over a wide range of current densities.

- Excellent solder wettability and thermal fatigue properties.

Crystal formation performed under different current densities

-

5ASD

-

10ASD

-

30ASD

Magnified images of crystals processed at current densities from 5 to 30 ASD. It can be seen that uniform crystals are formed at all current densities.

New aftertreatment agent

Au plating sealant (Metasu HS-15P)

Features

- Excellent corrosion resistance to corrosive environments (nitric acid exposure)

- No increase in contact resistance or decrease in solder wettability after treatment

- No emulsion type, without staining or unevenness

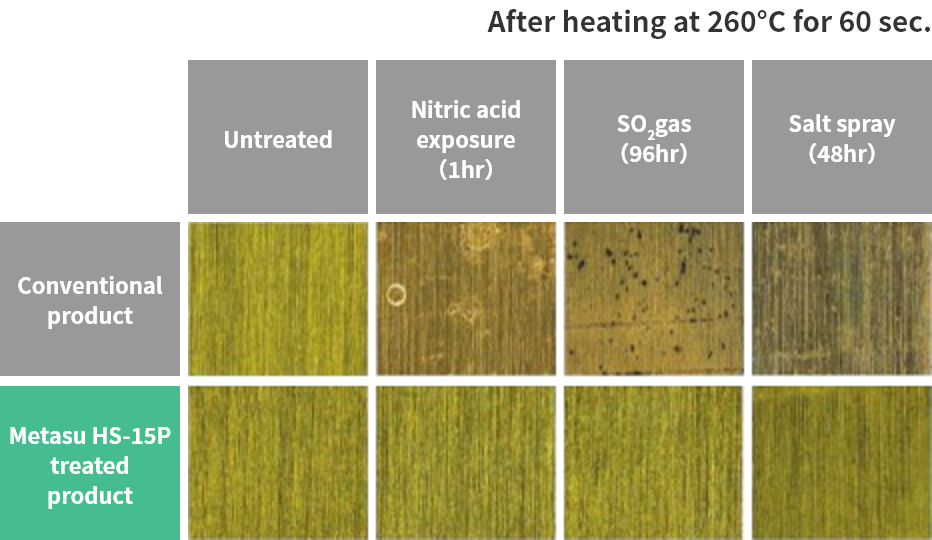

Corrosion resistance

Various types of corrosion resistance are greatly improved by sealing treatment

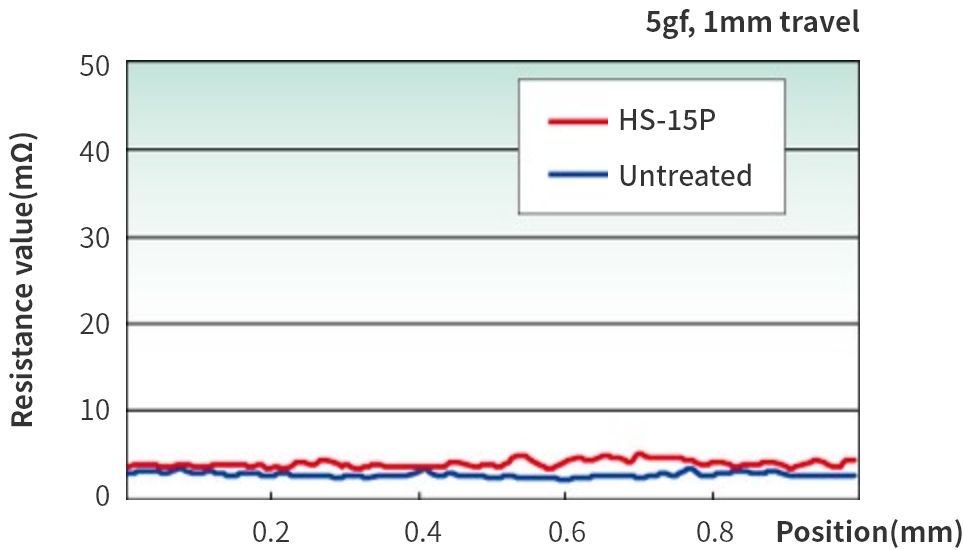

Contact resistance

No change in contact resistance after Metasu HS-15P treatment

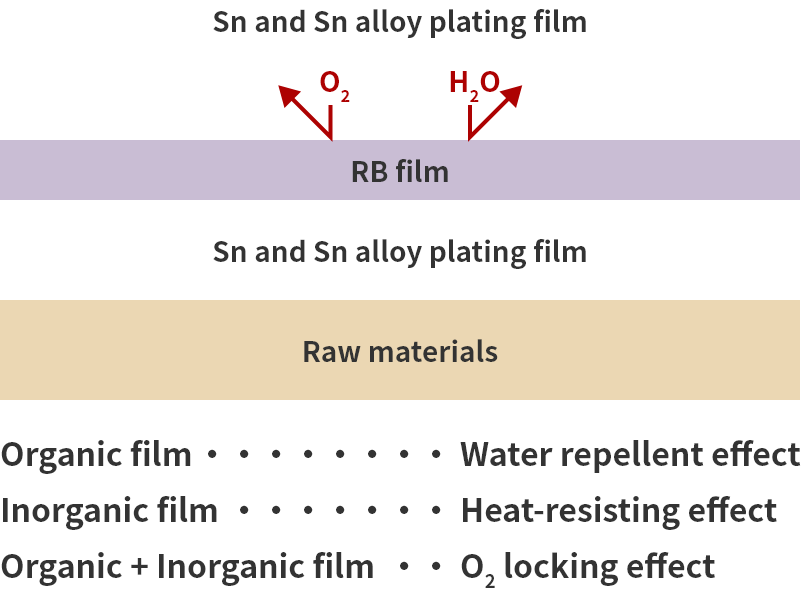

Anti-degradation agent for Sn plating solder wettability (Metasu HB-15)

Features

- Prevents degradation of solder wettability due to aging of Sn and Sn alloy plating film.

- No stains/unevenness after treatment.

- It does not affect Au or Ni plated films other than Sn plated films.

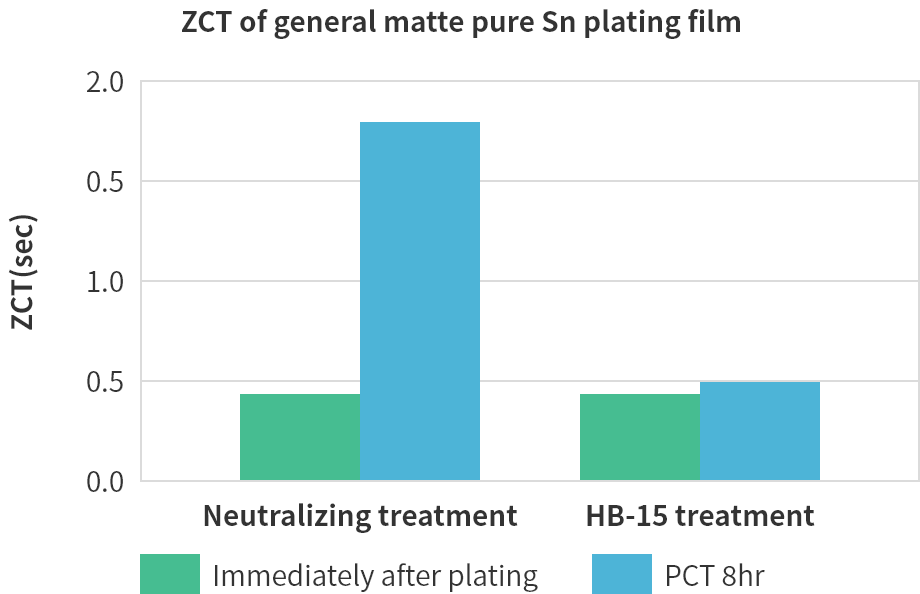

Solder wettability

Degradation of solder wettability is prevented even after PCT.

Prevention mechanism

By dipping treatment, an organic + inorganic film is formed.

Inquiries about the Chemical Products Division