Metasu YC

Metasu YC (completely chrome-free anti-rust coating)

Its excellent liquid properties enable treatment of even complex-shaped objects.

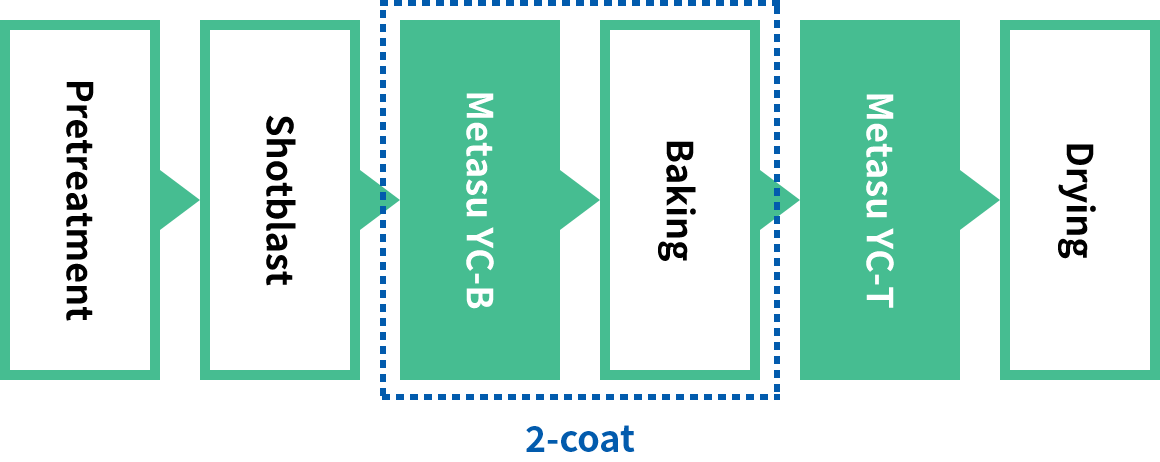

Metasu YC treatment process

Metasu YC-B (2-coat bake treatment) + Metasu YC-T (finish treatment)

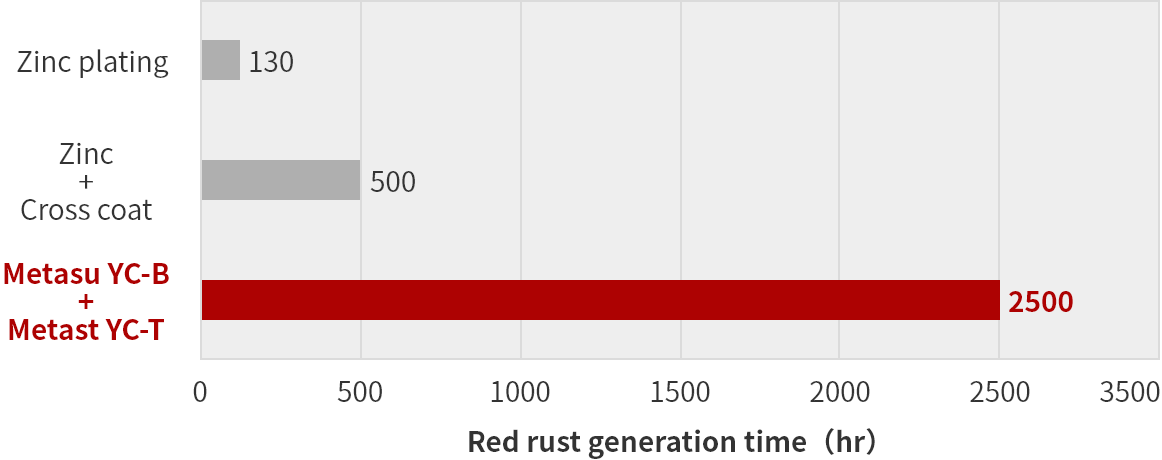

Corrosion resistance of Metasu YC (saltwater injection test results)

Compared to other plating, its unparalleled corrosion resistance has been proven.

3 Features of Metasu YC

Consistent corrosion resistance

Combined with a reactive finishing treatment (Metasu YC-T), consistent high corrosion resistance can be obtained even in scratched areas.

Corrosion resistance evaluation test of scratched area by cross cutting

(Salt spray test: JIS Z-2371)

-

Before evaluation

-

After 2000 hours No red rust occurs even in scratched areas.

Liquid accumulation control

The low viscosity of the treatment reduces the problem of poor liquid accumulation in recesses, which is a major issue in dip/spin treatment.

-

Cross socket head cap screw (M4)

-

Hexagon socket head cap screw (M6)

-

Hexagon socket head cap screw (M12)

Low baking temperature

Since the baking temperature is lower (approximately 260°C) than conventional treatments, there is less effect on the physical properties of the material (ductility and toughness) and it is also advantageous in terms of treatment costs.